Wehrli Custom Fabrication 2004.5-2010 LLY/LBZ/LMM Duramax Driver (Hot) Side 3" Intercooler Pipe Kit - WCF100352

WCF100352

-3" Hot Side Intercooler Pipe

-14g Mandrel Bent Aluminum Construction

-Silicone Boots

-T-Bolt Clamps

-Powder Coating

-No tuning required

-14g Mandrel Bent Aluminum Construction

-Silicone Boots

-T-Bolt Clamps

-Powder Coating

-No tuning required

Availability: WCFab Red, WCFab Grey, Candy Teal, Gloss White, and Gloss Black in stock and ships in 3-5 business days. 10-15 business day lead time on other colors.

Pricing:

$305.00

Description

LLY, LBZ, LMM Duramax One Piece High Flow 3" Driver Side Intercooler pipe. Replaces the 2 1/2" OEM inter cooler with a full 3" pipe. The OEM Pipe uses a reverse style bead roll design at the turbo which is prone for blowing off of the turbo under higher boost levels than stock. the WCFab inter cooler pipe uses straight high pressure rated boots, no angled boots.

No tuning required.

Replaces the following GM Part Numbers: 25789159, 15188717, 15188715

Video

Extra Details

Jason Wehrli, founder, CEO WCFab

Hey everyone. Welcome back to the channel. I'm Jason Wehrli with WCFab. Today, we have our 2005 to 2010 LLY-LBZ-LMM Duramax High Flow Driver's Side and Intercooler Pipe.

So we're going way back on this one. This is a product that I've been making since the inception of the company. The Intercooler pipes on the Duramax going as far back as the original LB7 model are some of the most failure prone parts on the Duramax platform, which is why it was one of the first items that we started producing way back in 2010, 2011. So this part over the years has had some improvements, used to be made from multiple pieces, used to make 'em one at a time, and tested 'em on every truck, actually in the beginning. We make quite a bit more of them now. So we've gone to a full mandrel bent component without any weld seams, and over the years we perfected the location and the installation and the fitment of these pipes. They've had some changes over the years for the better.

And what we've got today is our latest and greatest version of the Oh Five to 10, covering your LLY-LBZ-LMM Duramax. Some of the main failure points on the OEM system we'll touch on. First and foremost is the outlet boot at the Turbo. The Turbo Outlet sees the highest temperatures of the Intercooling system. The boot at the factory Turbo Outlet is a very thin silicone boot, and they're notorious for failing and ripping open. We designed our boot as a five-ply silicone boot with a high-temperature aramid liner. The aramid liner on these boots is designed to withstand over 500 degrees, so the boot does not break down and fail like the OEM does. Additionally, we've incorporated a steel wire reinforcement in the center section of the boot between the outlet of the turbo and the inlet of our pipe.

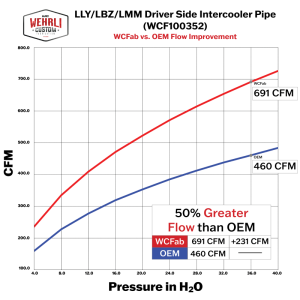

That short section in the middle has an internal wire reinforcement, which doesn't allow that boot to expand. One of the reasons that the OEM boots fail is they start blowing up and expanding; when they expand, they tear and start leaking. That boot connects to our three-inch 14 gauge mandrel bent aluminum intercooler pipe, an upgrade from the two-and-a-half-inch diameter factory unit. Going from that two-and-a-half inch to our three-inch is a 50% increase in CFM flow over the OEM unit. That increase increases turbo spool up, quicker throttle response, and lower EGTS. One of the other major downfalls of the OEM Intercooler pipe design is it uses a reverse-style bead roll at the boot connection instead of having an external bead roll hump on the pipe, which is there to keep the boot and clamp from sliding off.

The factory design is an internal style beadroll notorious for allowing the boot and clamp to slide right off the end of the pipe working down to the Intercooler connection. On the hot side Intercooler pipe is our three inches five-ply silicone boot. That is a straight connection to the intercooler. Another area of improvement over the factory design is the factory using an elbow-style boot connection at the Intercooler. That elbow is a longer boot and is a longer cross section area for the boot to expand and eventually lead to failure. So, the straight connection is more robust and reliable than the angled-style boot connection. The Intercooler pipes are a simple and effective upgrade on all model Duramax. They're easy to install, no tuning required, no check engine lights, or anything to worry about, giving you more peace of mind and a little performance increase.

Lastly, our intercooler pipe on the table is shown in our WCFab Gray Signature color. All done here in-house in our state-of-the-art Powder Coat Facility. WCFab Gray and Red are two of our several in-stock quick-to-ship colors, which you'll see noted on our website, or you can choose from one of our 35 standard colors and, with a slight upcharge, any custom color. If you would like, you're purchasing Intercooler pipe upgrades for your Duramax, be sure to check out our cold side upgrades as well as our high flow bundle kit packages, which is a lot of our intake components bundled together in one kit to save you money versus buying everything individually. Thanks a lot for watching.

Hey everyone. Welcome back to the channel. I'm Jason Wehrli with WCFab. Today, we have our 2005 to 2010 LLY-LBZ-LMM Duramax High Flow Driver's Side and Intercooler Pipe.

So we're going way back on this one. This is a product that I've been making since the inception of the company. The Intercooler pipes on the Duramax going as far back as the original LB7 model are some of the most failure prone parts on the Duramax platform, which is why it was one of the first items that we started producing way back in 2010, 2011. So this part over the years has had some improvements, used to be made from multiple pieces, used to make 'em one at a time, and tested 'em on every truck, actually in the beginning. We make quite a bit more of them now. So we've gone to a full mandrel bent component without any weld seams, and over the years we perfected the location and the installation and the fitment of these pipes. They've had some changes over the years for the better.

And what we've got today is our latest and greatest version of the Oh Five to 10, covering your LLY-LBZ-LMM Duramax. Some of the main failure points on the OEM system we'll touch on. First and foremost is the outlet boot at the Turbo. The Turbo Outlet sees the highest temperatures of the Intercooling system. The boot at the factory Turbo Outlet is a very thin silicone boot, and they're notorious for failing and ripping open. We designed our boot as a five-ply silicone boot with a high-temperature aramid liner. The aramid liner on these boots is designed to withstand over 500 degrees, so the boot does not break down and fail like the OEM does. Additionally, we've incorporated a steel wire reinforcement in the center section of the boot between the outlet of the turbo and the inlet of our pipe.

That short section in the middle has an internal wire reinforcement, which doesn't allow that boot to expand. One of the reasons that the OEM boots fail is they start blowing up and expanding; when they expand, they tear and start leaking. That boot connects to our three-inch 14 gauge mandrel bent aluminum intercooler pipe, an upgrade from the two-and-a-half-inch diameter factory unit. Going from that two-and-a-half inch to our three-inch is a 50% increase in CFM flow over the OEM unit. That increase increases turbo spool up, quicker throttle response, and lower EGTS. One of the other major downfalls of the OEM Intercooler pipe design is it uses a reverse-style bead roll at the boot connection instead of having an external bead roll hump on the pipe, which is there to keep the boot and clamp from sliding off.

The factory design is an internal style beadroll notorious for allowing the boot and clamp to slide right off the end of the pipe working down to the Intercooler connection. On the hot side Intercooler pipe is our three inches five-ply silicone boot. That is a straight connection to the intercooler. Another area of improvement over the factory design is the factory using an elbow-style boot connection at the Intercooler. That elbow is a longer boot and is a longer cross section area for the boot to expand and eventually lead to failure. So, the straight connection is more robust and reliable than the angled-style boot connection. The Intercooler pipes are a simple and effective upgrade on all model Duramax. They're easy to install, no tuning required, no check engine lights, or anything to worry about, giving you more peace of mind and a little performance increase.

Lastly, our intercooler pipe on the table is shown in our WCFab Gray Signature color. All done here in-house in our state-of-the-art Powder Coat Facility. WCFab Gray and Red are two of our several in-stock quick-to-ship colors, which you'll see noted on our website, or you can choose from one of our 35 standard colors and, with a slight upcharge, any custom color. If you would like, you're purchasing Intercooler pipe upgrades for your Duramax, be sure to check out our cold side upgrades as well as our high flow bundle kit packages, which is a lot of our intake components bundled together in one kit to save you money versus buying everything individually. Thanks a lot for watching.

Details

- WCF100352

- WCF100352

- Wehrli Custom Fabrication

- WCFab Red, WCFab Grey, Candy Teal, Gloss White, and Gloss Black in stock and ships in 3-5 business days. 10-15 business day lead time on other colors.

- New

Shipping Information

- Item Requires Shipping

- 10.0 lbs.

- W12.0000” x H12.0000” x L36.0000”

- Free Shipping!

- This item ships in its own box.

Customer Reviews

Total Reviews (0)

Total Reviews (0)

You must login to post a review.

Write the First Review!